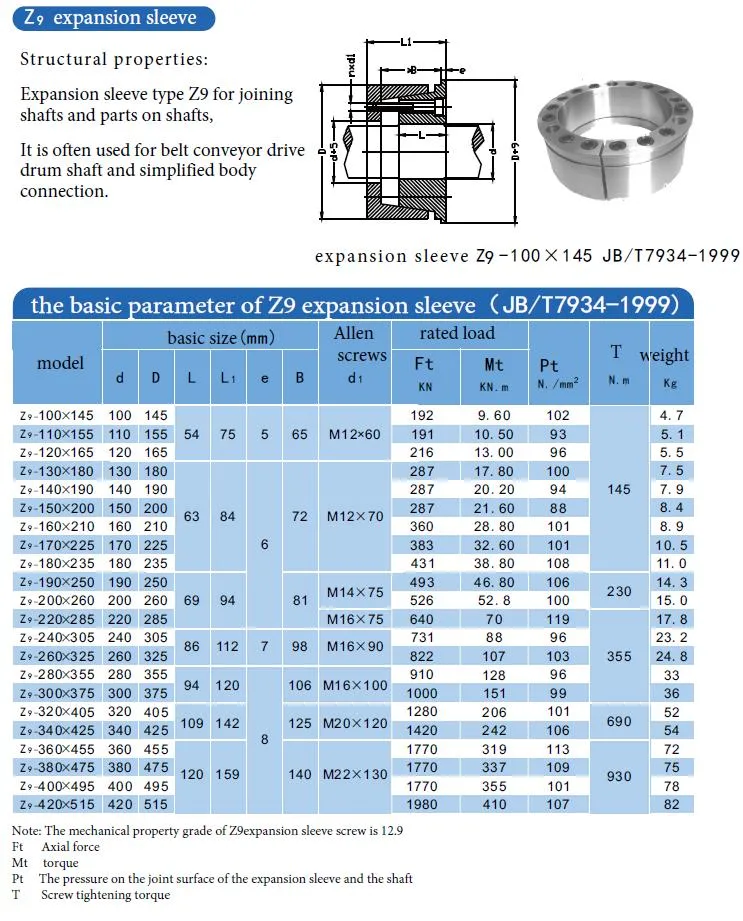

Z9 Expansion Sleeve/Locking Assembly /Taper Lock Bushing

Basic Info.

| Transport Package | Wood Box / Carton Box |

| Specification | as requirement |

| Trademark | TL |

| Origin | Guang Zhou |

| HS Code | 8483900090 |

| Production Capacity | 50000 Pieces /Year |

Product Description

Product Description

| product | Z9 expansion sleeve |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

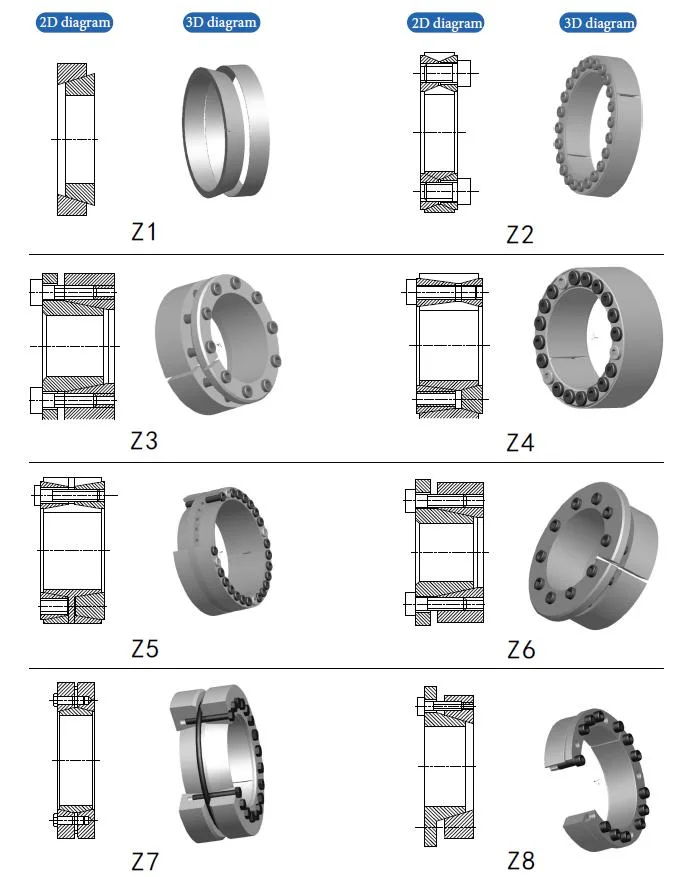

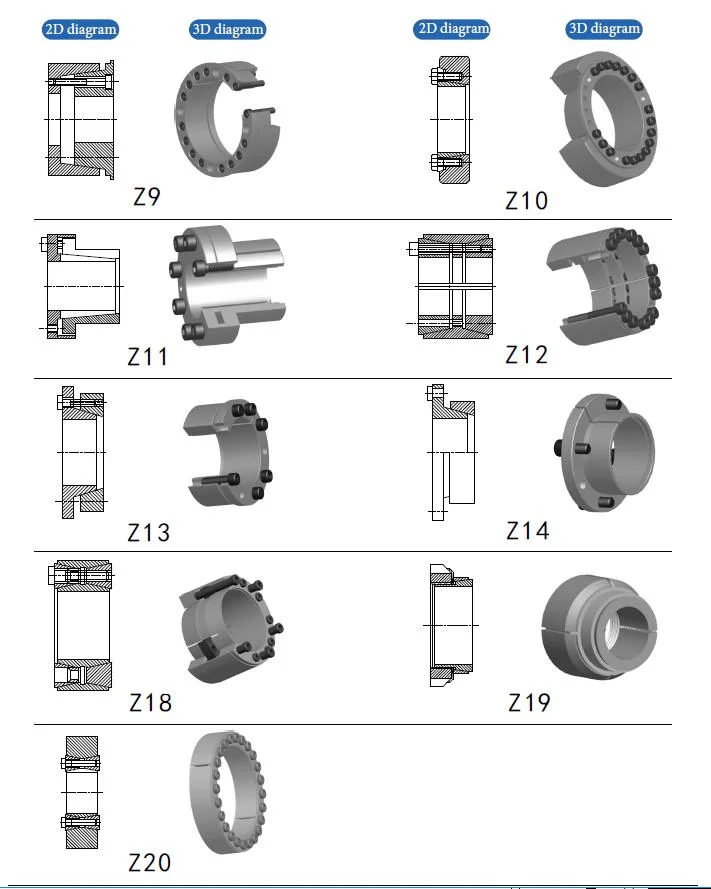

| kind | expansion sleeve Z1/Z2/Z3/Z4/Z5/Z6/Z7/Z8/Z9/Z10/Z11/Z12/Z13/Z14/Z18/Z19 |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding...... |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

shipping

sample orders delivery time:10-15 working days as usual15-20 working days in busy seasonlarge order leading time :20-30 working days as usual30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what's more ,we have got ISO9001 and SGS certificate .

2 .How to install the tensioning sleeve

1. Clean the surface of the joint to make it free of dirt, corrosion and damage.

2. On the surface of the cleaned expansion sleeve and the surface of the joint, evenly apply a thin layer of lubricating oil.

3. Push the connected parts to the shaft to reach the position specified in the design.

4. Smoothly load the expansion sleeve of the loosened screw into the coupling hole, to prevent the tilt of the joint, and then tighten the screw by hand

3 .How to maintain the expansion sleeve

1. After installation, apply a layer of anti-rust grease to the exposed end face of the expansion sleeve and the head of the screw.

2. On machines that work in the open air or have a poor working environment, anti-rust grease should be applied to the upper end face of the exposed expansion sleeve regularly.

3. The expansion sleeve that needs to work in the corrosive medium should take special protection (such as a cover plate) to prevent the expansion sleeve from rusting.